To ensure that incoming parts meet spec, some manufacturers perform incoming inspection. This is typically a sampling process, but in some cases can also be 100% inspection. A solid incoming inspection process reduces defects and costly manufacturing problems down the road.

To ensure that incoming parts meet spec, some manufacturers perform incoming inspection. This is typically a sampling process, but in some cases can also be 100% inspection. A solid incoming inspection process reduces defects and costly manufacturing problems down the road.

Incoming inspection’s popularity has varied through the years. In some industries it was eliminated completely, by putting the complete onus for incoming part quality on the suppliers, whereas in other industries it has remained a staple. Most manufacturers now recognize that part quality is a shared responsibility between the supplier and the buyer, and the two must work together to strike the right balance.

In many quarters, incoming inspection is making a comeback thanks to the capabilities provided by automated 3D laser scanners such as those made by ShapeGrabber.

Inspect Incoming Parts Quickly & Thoroughly

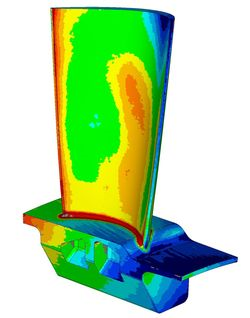

Using the right 3D scanner, inspectors can quickly determine whether a supplier’s part meets its specifications, without having to do a complete part layout. An automated 3D scanner such as the ShapeGrabber Ai810 can capture millions of data points from even the most complex-shaped part within just minutes. The resulting point cloud can then be quickly compared directly to a 3D CAD model or to a known good part. This provides rapid validation of the supplier’s quality control process.

ShapeGrabber 3D Scanner Benefits

ShapeGrabber’s automated 3D laser scanner technology is well proven and especially useful for incoming inspection because:

- It’s fast. You don’t need to rely on a few sample points collected with calipers or a slow CMM: capture millions of data points in minutes.

- It’s easy. The visual nature of the results makes it possible to quickly validate incoming parts, without the need to do a complete spec by spec layout. This comparison can be automated, allowing operators to perform repetitive validation tasks with minimal involvement and training.

- It handles complex shapes. Curves and multiple features aren’t a problem.

To determine whether a ShapeGrabber 3D scanner is right for your incoming inspection process, please contact us for an assessment or free part scan.