Background:

Founded in 1972, Viking Plastics is a global supplier of engineered, injection molded, and assembled sealing solutions. An ISO and TS certified company, Viking Plastics develops a variety of caps, sealing solutions and custom molded components.

Situation:

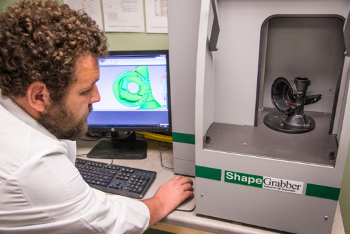

To further enhance Viking Plastics’ quality department and the company’s ability to make complex parts, Viking Plastics acquired an automated 3D scanner from ShapeGrabber.

The ShapeGrabber Ai310 3-D scanner takes a full 360° scan of a part and translates it into a point cloud, which can then be overlaid to CAD. Using a color map, Viking Plastics is able to determine every high or low spot in a part using dimensioning tolerances taken from 2D print or CAD. With this information, the company can create a 3D PDF file that can be sent to the customer to show areas for potential design improvements.

Solution:

With the addition of the ShapeGrabber Ai310 scanner, Viking Plastics now has the ability to compare actual measurements to the CAD Model data and then visualize them in a color map. This helps customers better understand the product features, increases the quality of Viking Plastics products, speeds quality control activities, and reduces costs.

Viking Plastics Accolades

Testifying to the dedication and commitment of the Viking Plastics Team, the company has received supplier excellence awards from Delphi Corporation, General Motors, and Ford Motor Company. To aid in sustaining those standards of excellence, Viking Plastics maintains ISO/TS 16949 and ISO 14001 certifications at its facility in Corry, Pa.

- ISO/TS 16949:2009

- ISO 14001:2004

- General Motors Supplier Quality Excellence Award 2014 & 2015

- Erie Employer of the Year 2014

- Nexteer Perfect Quality Award 2013