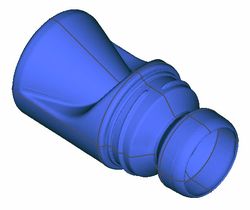

Manufacturers who use a 3D scanner in their quality inspection processes sometimes need to inspect the inside of a part. In such situations, 3D scanners are used along side CT scanners.

A 3D laser scanner like a ShapeGrabber scanner can provide fast, accurate and radiation-free scanning of the complete external surface of a part, no matter how complex its shape. The 3D scan data can then be analysed using graphical tools such as color mapping and whisker plots, or more traditional methods such as cross-sectioning and point to point dimensioning, to obtain accurate measurements of the part.

A 3D laser scanner like a ShapeGrabber scanner can provide fast, accurate and radiation-free scanning of the complete external surface of a part, no matter how complex its shape. The 3D scan data can then be analysed using graphical tools such as color mapping and whisker plots, or more traditional methods such as cross-sectioning and point to point dimensioning, to obtain accurate measurements of the part.

However, no 3D laser scanner can measure the inside of a part without cutting the part to access those features. X-ray computed tomography, also known as CT scanning, can be used in conjunction with a 3D scanner when internal inspection is necessary, and it is not possible to cut the part.

Both 3D scanners and CT scanners provide non-contact scanning. The difference is that CT scanning employs x-ray technology to capture interior features of parts, including complex or free-form shapes. These two types of scanners are often used in complement and do not replace each others’ function. For surface-scan applications where speed and accuracy are paramount, a 3D laser scanner is ideal. When internal inspection is the priority, and one is willing to compromise on speed, a CT scanner is the right choice. CT scanner operation may require protective radiation gear (and safety training), while laser scanning has no such considerations.

Every type of 3D scanner has optimal applications and uses. Talk to ShapeGrabber about your specific inspection and measurement needs. We’ll be happy to advise you about whether a 3D laser scanner can be integrated into your quality inspection process.