Comparison to CMM

ShapeGrabber’s industrial 3D scanners complement traditional optical coordinate measuring machines (CMMs).

ShapeGrabber’s industrial 3D scanners complement traditional optical coordinate measuring machines (CMMs).

Many ShapeGrabber customers use our 3D scanners in conjunction with or in place of traditional CMM machines in situations like these:

- The part has a complex shape or compound curves that a traditional CMM cannot effectively measure

- Time-to-measure must be minimized to reduce cost and reduce delays

- Quality control or inspection is required for the entire surface area of the part

- The part is not rigid enough to sustain its shape through CMM contact

- Investment in precise fixtures must be minimized to reduce cost

- There is a shortage of trained resources available to run complex CMMs

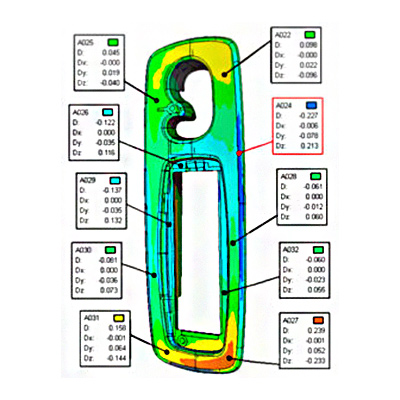

CMMs are known for their high single-point accuracy, while ShapeGrabber automated 3D scanners are known for their speed and ability to measure whole complex-shaped parts. ShapeGrabber laser scanners are used for:

- Situations where fixturing is difficult or impossible

- Non-contact scanning with very high density output

- Fast data acquisition: up to 350,000 points per second

- Scanning the entire surface area and very complex shapes

- Scanning material of any rigidity or density

- Exceptional ease of use – CAD training is not required

If you are considering replacing or complementing your CMMs, please contact us!