3D Scanner Articles

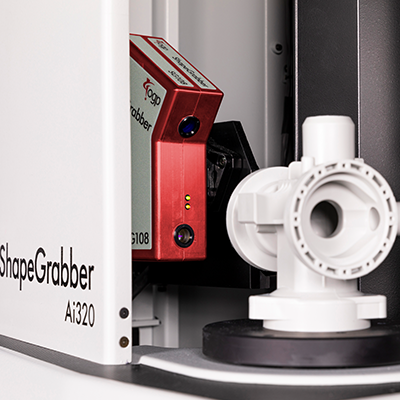

ShapeGrabber Featured in Today’s Medical Developments

August 16, 2022A ShapeGrabber expert discusses use and benefits when using OGP’s ShapeGrabber scanners in the medical manufacturing industry.

Read More >Virtualize Inspection Gauges to Slash Manufacturing Costs

December 7, 2017While gauges have been invaluable in the manufacturing quality process since the industrial age, they represent certain drawbacks for today’s manufacturers, who are under constant pressure to reduce costs and increase efficiencies while maintaining high quality.

Read More >3D Scanning for Incoming Inspection

November 2, 2017To ensure that incoming parts meet spec, some manufacturers perform incoming inspection. This is typically a sampling process, but in some cases can also be 100% inspection. A solid incoming inspection process reduces defects and costly manufacturing problems down the road.

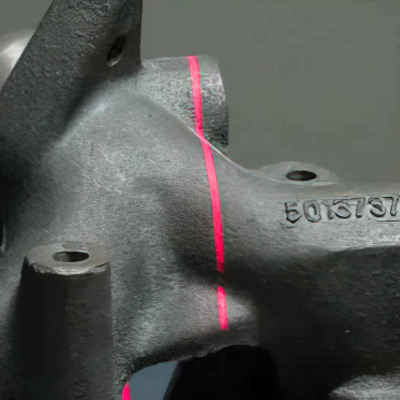

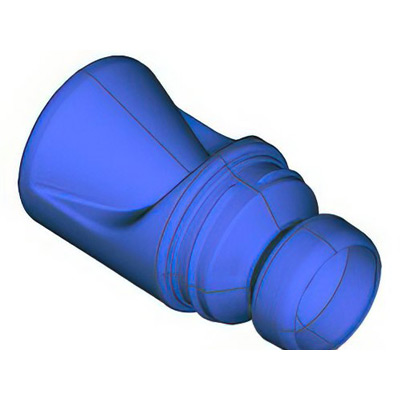

Read More >Part Replication with a 3D Scanner

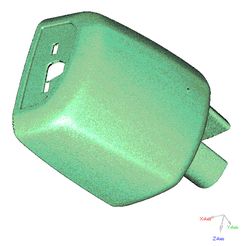

October 3, 2017At some point, most manufacturers will need to replicate a part for which there is no original CAD file. Perhaps it’s a tool nearing the end of its life, a legacy part that was designed in the pre-CAD days, or a component that was modified after the CAD model was created…

Read More >Keep Your 3D Scanner Investment Working for You

September 20, 2017A professional 3D scanner is an investment, and one that should last. Here are a couple of tips to ensure that your scanner serves you well for many, many years.

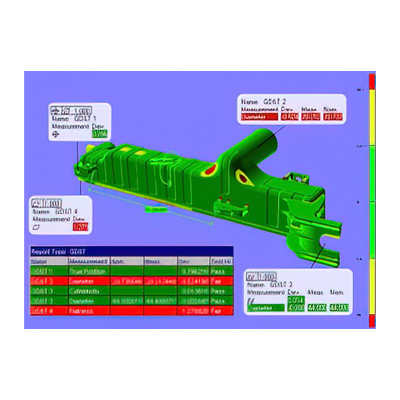

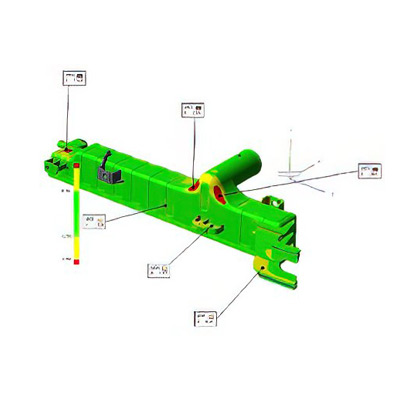

Read More >First Article Inspection with a 3D Scanner

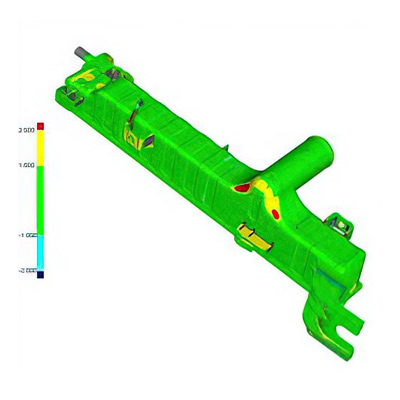

August 8, 2017Performing a thorough First Article Inspection (FAI) on new production parts is the norm across most industries, but the methods and tools used for FAI vary greatly. Recently, manufacturers have adopted 3D scanners as their main tool for FAI.

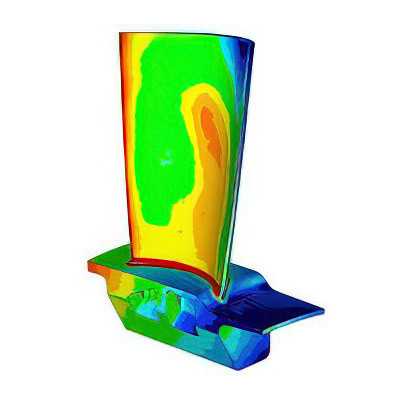

Read More >Bringing Prototypes to Life with a 3D Scanner

May 17, 2017Prototyping is a critical step in manufacturing, and accurate prototypes are required to prove out concept designs, validate research, and to help stakeholders visualize and buy in to new product innovations. 3D scanners are particularly effective at describing and representing even the most complex shape in CAD, CAM, or CAE systems.

Read More >Achieving Cost-Effective Model-Based Design with a 3D Scanner

April 5, 2017For many original design and equipment manufacturers (OEMs/ODMs), model based design (MBD) is becoming a favoured method to flow requirements to their manufacturing suppliers. But it may be difficult for many manufacturers to support while maintaining promised lead times and keeping prices competitive. But, a 3D scanner provides an answer to this conundrum.

Read More >Enhance Injection Mold Tryouts with a 3D Scanner

March 1, 2017Injection-mold tryouts provide mold makers with an important means of testing and documenting the quality of their products for customers. Tryouts are used to prove out the mold and repair any defects before it is shipped to customers.

Read More >Measuring & Inspecting Medical Parts with a 3D Scanner

January 3, 2017Medical device components, such as implants and prosthetics, pose a number of challenges for manufacturers. In addition to being highly complex, they need to be extremely reliable for use in human patients. Moreover, some medical devices are custom “one-of-a-kind” parts with very specific measurements for an individual patient.

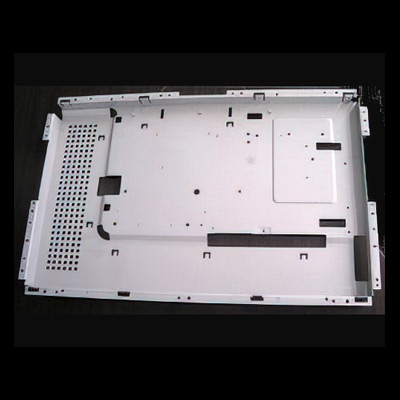

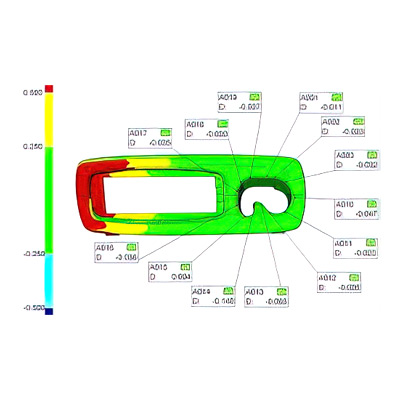

Read More >Measuring Metal Stampings with a 3D Scanner

December 5, 2016To overcome the difficulties of measuring metal stampings, many companies in the automotive, aerospace, computing, consumer electronics, and other industries turn to 3D scanners.

Read More >Retrofitting your CMMs with a 3D Laser Scanhead: Is it Worth it?

November 1, 2016Do you want to take advantage of 3D scanning to speed up your dimensional measurements? If you already own a traditional Coordinate Measuring Machine (CMM), you may have heard that you can retrofit it to convert it into a 3D scanner.

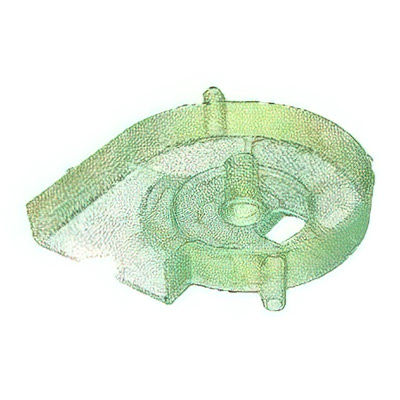

Read More >Measuring Soft Components with a 3D Scanner

September 1, 2016As a non-contact measurement solution, a 3D scanner excels at measuring soft components, such as rubber seals or foam parts. Automated 3D scanners offer a fast, accurate, and non-invasive way to scan even the most complex flexible shapes.

Read More >The 3D Scanning Experience

July 3, 2016As someone who’s used almost every variety of scanner on the market, including structured light, LIDAR, CT, portable, and automated 3D scanners, I’ve noticed some similarities – and shortcomings – when it comes to industrial scanners.

Read More >3D Inspection of the Inside of a Part

April 19, 2016Manufacturers who use a 3D scanner in their quality inspection processes sometimes need to inspect the inside of a part. In such situations, 3D scanners are used along side CT scanners.

Read More >3D Scanners in Industrial Environments

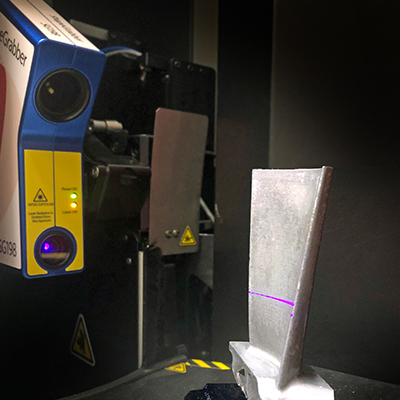

March 7, 2016In a manufacturing environment, an industrial 3D scanner – such as those we produce at ShapeGrabber – is ideal. These 3D scanners are designed to function in noisy, dusty manufacturing environments and in ambient lighting. They are also designed for use by technicians and operators rather than engineers or scientists.

Read More >Inspecting Transparent or Reflective Parts with a 3D Laser Scanner

October 7, 2015Optical light-based inspection can be tricky if the part being inspected is transparent or reflective. In this article we’ll explain why the challenge exists and how it is easily overcome for 3D scanning projects.

Read More >3D Metrology vs. Machine Vision: Understanding the Differences

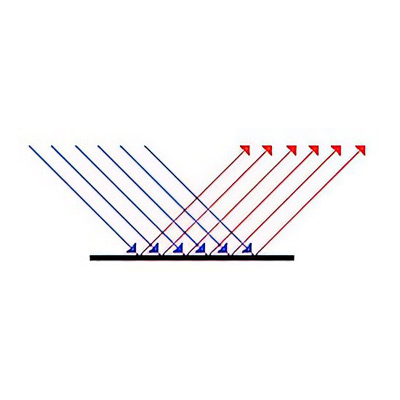

February 11, 2015When researching a dimensional quality control solution, it is important to understand the difference between 3D scanners and machine vision systems. While both types of equipment are used in quality control, they are used to achieve different results.

Read More >Enhance Your Lean Manufacturing Program with a 3D Laser Scanner for Quality Inspection

September 12, 2014Nearly every manufacturer is now implementing Lean Manufacturing principles. In today’s competitive environment, the drive for continuous improvement is a necessary factor of success for manufacturers in every industry.

Read More >Improving Quality Control Processes with a 3D Scanner

January 7, 2013One of the many benefits of a 3D laser scanner is that it is suitable in most quality control environments. In particular, a 3D scanner can enhance 100% inspection, statistical process control (SPC), and part production approval processes (PPAP).

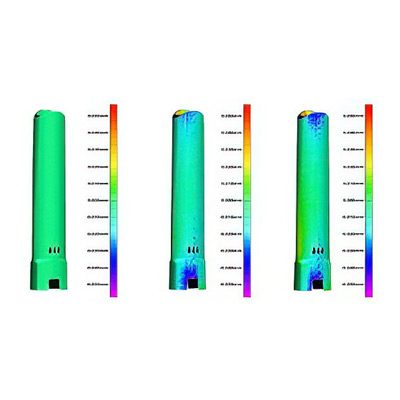

Read More >Assess How a Part Changes Over Time Using a 3D Laser Scanner

August 20, 20123D laser scanners are invaluable tools for part comparisons, such as comparing a manufactured part to its intended design (CAD model) to analyze deviations and comparing a new part to an older known good part to troubleshoot problems. An equally valuable but less well-known method is to compare a part to itself.

Read More >3D Laser Scanning: Solving the Toughest Quality Inspection Problems

April 19, 2012Manufacturers come to us with many different complex parts in a variety of sizes and materials, but one problem arises frequently: “I can’t figure out why this part is coming out off spec!”

Read More >